It makes for better rip cuts and i can make flat bottom grooves too. These blades are designed for both ripping and cross cutting on various materials.

Understanding Saw Blade Essentials Make

Understanding Saw Blade Essentials Make

the rip teeth on standard combination blades are known as

the rip teeth on standard combination blades are known as is a summary of the best information with HD images sourced from all the most popular websites in the world. You can access all contents by clicking the download button. If want a higher resolution you can find it on Google Images.

Note: Copyright of all images in the rip teeth on standard combination blades are known as content depends on the source site. We hope you do not use it for commercial purposes.

Carbide tipped blades are so hard that they must be sharpened by impregnated.

The rip teeth on standard combination blades are known as. The outer edge of a blade features teeth and gullets gaps between the teeth and this is one of the things. It has a standard 0126 kerf. This is known as a combination blade as it has features of both rip and crosscut blades and can handle both types of cuts.

Learn vocabulary terms and more with flashcards games and other study tools. The valleys between the teeth on a saw blade are known as. The teeth on a carbide tipped blade are similar to the rip teeth on a high speed steel.

Teeth combination also is known as the comb these blades are ideal for any workshop owner to have. As with all 10 combination blades there are 10 sets of 5 teeth. Rip cut blades are designed specifically for rip cuts crosscut blades for crosscuts and so on.

With this blade there isnt anything to do with the ripped edge straight to glue up or finish. The number of teeth is crucial the more teeth the blade has the smoother the cut is while blades with fewer teeth produce rough cuts known as rip cuts. The teeth on such blades come with a group arrangement of 5 with a huge hollow in the middle of the teeth.

Its going to give you very good rip and crosscuts in both hardwoods and softwoods as well as easily being able to deal with sheet materials. There is also a third type of circular saw blade which is for general use. Its a standard size 10 50 teeth combination blade.

Start studying chapter 4 determine the sequence and timing. Versatile carbide tipped blade is probably the most widely used by carpenters. One ftg that makes the rough cut and 4 atb.

The teeth on these blades are only relieved or chamfered on one side. I now use the option 1 version which has some raker teeth with clipped corners mixed in with the standard atb teeth. Combination blades also come with a higher tooth count up to 80 teeth on some of the larger blades.

You can find specialist rip cut blades crosscut blades combination blades framing blades plywood blades thin kerf blades and more. The purpose of this design is to increase the efficiency of ripping a wide variety of materials especially hard materials. There is a sub category of tgc blades known as c tcg.

The number of saw blade teeth is determined by tip teeth per inch that usually ranges from 3 to 24 tip for reciprocating saws. I too use a forrest wwii blade but not the standard one. This is alternated from tooth to tooth much as atb blades have their teeth alternated.

Freud 12 X 60t Thin Kerf Combination Blade Lu83r012 Miter Saw

Freud 12 X 60t Thin Kerf Combination Blade Lu83r012 Miter Saw

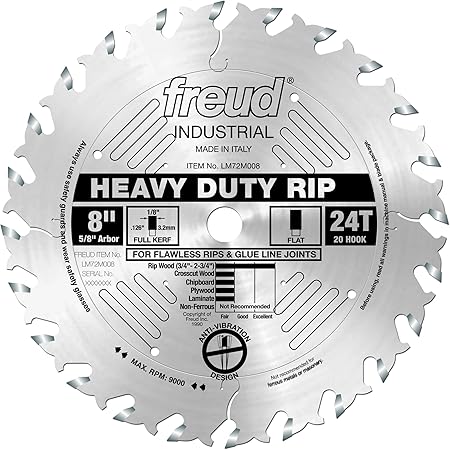

Freud 8 X 24t Heavy Duty Rip Blade Lm72m008 Circular Saw

Freud 8 X 24t Heavy Duty Rip Blade Lm72m008 Circular Saw

Combination Saw Blades All Purpose Combo Saw Blade W Carbide Tip

Combination Saw Blades All Purpose Combo Saw Blade W Carbide Tip

Buck Saw Blade Freud Tk906 Avanti 10 Inch 50 Tooth Atb Thin Kerf

Century Drill Tool Corp 10253 5 3 8 24tcombo Saw Blade

Century Drill Tool Corp 10253 5 3 8 24tcombo Saw Blade

Cmt 221 060 10 Industrial Cabinetshop Saw Blade 10 Inch X 60

Cmt 221 060 10 Industrial Cabinetshop Saw Blade 10 Inch X 60

Stanley Products Steel Circular Saw Blades 10 In 40 Teeth

Stanley Products Steel Circular Saw Blades 10 In 40 Teeth

Diablo D1050x Combination Saw Blade Table Saw Blades Amazon Com

Diablo D1050x Combination Saw Blade Table Saw Blades Amazon Com

Choosing A Saw Blade For Your Table Saw

Selecting The Right Table Saw Blade Cabinetmaker Warehouse

Selecting The Right Table Saw Blade Cabinetmaker Warehouse